Automation

Seals play a vital role in the automation industry and are widely used in various automation equipment and systems.

- Home

- Lq-project

- Automation

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

(17-1) NO23, Beisizhong Lu, Tiexi District, Shenyang, Liaoning,China.

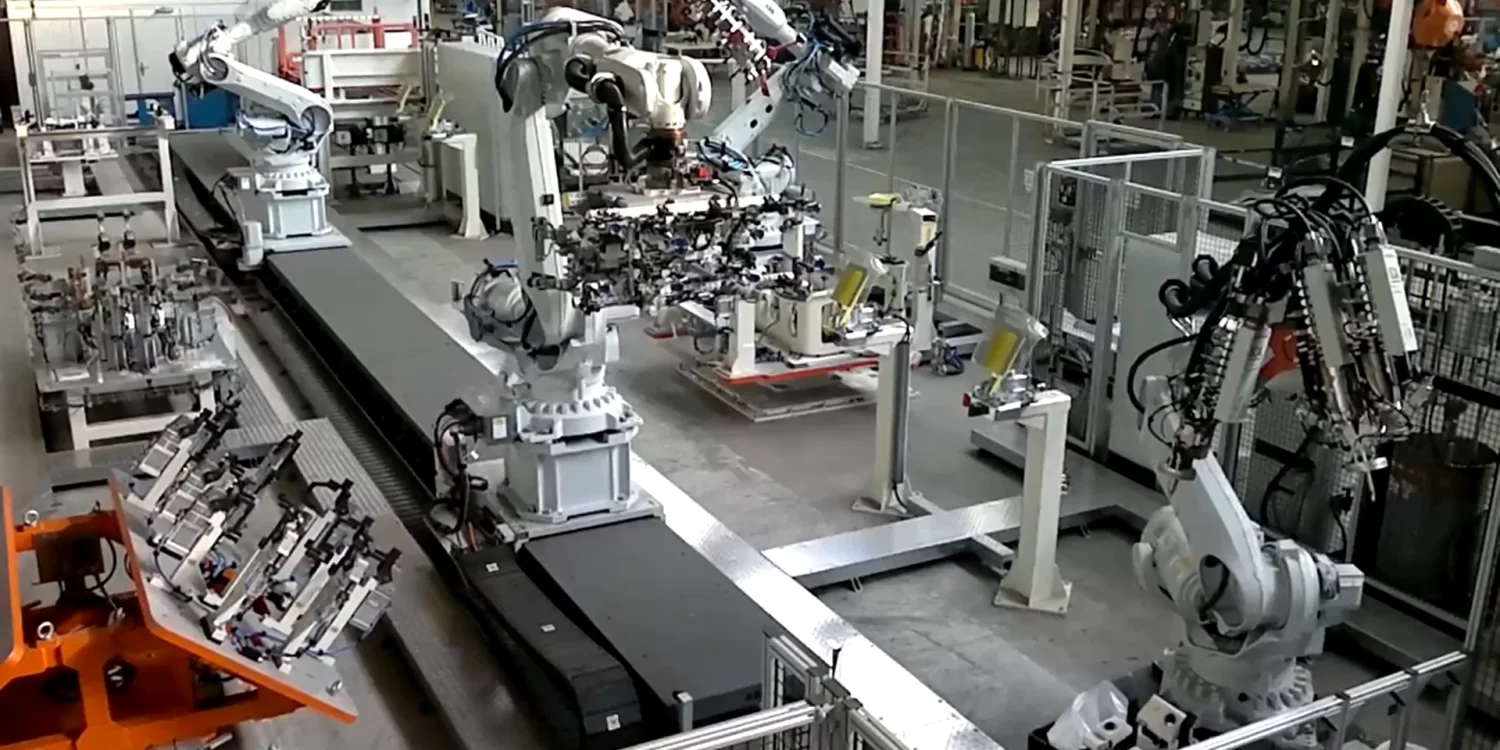

Industrial robots

Joints: The joints of industrial robots are key parts of movement, and seals are needed to prevent lubricating oil leakage and the intrusion of external dust and impurities. For example, rotary joints usually use a combination of labyrinth seals and sealing rings, which can not only ensure the flexible rotation of the joints, but also effectively seal. Linear motion joints often use dust rings and piston seals to ensure reliable sealing performance during linear reciprocating motion and extend the service life of the joints.

Driver and motor: The robot's driver and motor need to be well sealed to prevent moisture, oil, etc. from entering and affecting its electrical performance and normal operation. Common sealing methods include using sealants to seal the motor housing and using rubber sealing rings to seal the motor shaft extension to ensure the cleanliness and dryness of the internal environment.

Automated production line

Conveying equipment: Seals need to be installed at the roller shaft end of the belt conveyor to prevent materials and dust from entering the bearing and affecting the rotation of the roller. Seals are also used at the chain joints of chain conveyors to reduce the leakage of lubricating oil and prevent impurities from entering the chain to ensure smooth transmission.

Processing equipment: In automated processing equipment, such as the spindle box and feed mechanism of CNC machine tools, seals are used to prevent the leakage of cutting fluid and lubricating oil, as well as the intrusion of chips, dust, etc. For example, the spindle box usually uses double-lip seals or mechanical seals to ensure that good sealing performance can be maintained under high-speed rotation and high-pressure cutting fluid spray, protecting key components such as the spindle and bearings.

Assembly equipment: Pneumatic clamps and hydraulic clamps in automated assembly equipment require seals to ensure stable pressure and no leakage of the medium. For example, O-rings or Y-rings are used to seal the cylinder piston of the pneumatic clamp, so that the cylinder can generate sufficient clamping force and maintain reliable sealing performance during frequent movements.

Automated testing equipment

Optical testing equipment: Optical testing equipment such as microscopes and spectrometers require seals to protect optical components and prevent dust and water vapor from entering the equipment, affecting optical imaging and detection accuracy. Rubber seals or sealing pads are usually used to seal the equipment's housing, lens interface and other parts to create a relatively stable internal environment.

Electronic testing equipment: In electronic component testing equipment, such as circuit board testers and semiconductor testers, seals are used to prevent static electricity, dust and moisture from affecting precision electronic components and detection probes. For example, an elastic seal is used at the probe interface of the tester, which can not only ensure good contact between the probe and the object being tested, but also prevent external factors from interfering with the test results.

Smart warehousing equipment

Shelf system: The shelves of automated warehouses use seals at some key connection points to prevent the shelves from being affected by moisture, rust, and other reasons during long-term use. For example, the connection between the column and the base of the shelf is sealed with sealant to prevent rain and moisture from entering, thereby extending the service life of the shelf.

Logistics robots: The battery compartment, drive system, and control system of logistics robots such as AGV (automatic guided vehicle) and AMR (autonomous mobile robot) all need to be sealed. The seal of the battery compartment can prevent electrolyte leakage and external water vapor from entering, protecting the safety and performance of the battery. The sealing of the drive system and control system can prevent dust, oil, etc. from damaging the motor, controller and other components, ensuring the stable operation of the robot in a complex storage environment.

D Eleven supply standard and customized seals for Automation industry. Include as below:

For more information, contact our expert technical team.

Call+8613504978509 or email info@d-eleven.cn