Mechanical Seals

Seals are widely used in the mechanical field. They are important components to ensure the normal operation of various mechanical equipment and improve performance and reliability.

- Home

- Lq-project

- Mechanical Seals

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

(17-1) NO23, Beisizhong Lu, Tiexi District, Shenyang, Liaoning,China.

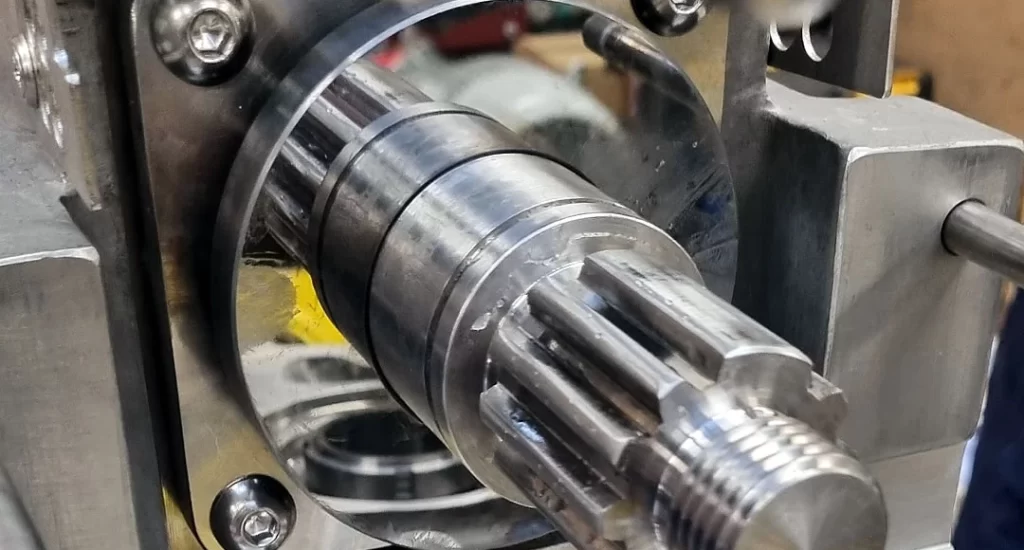

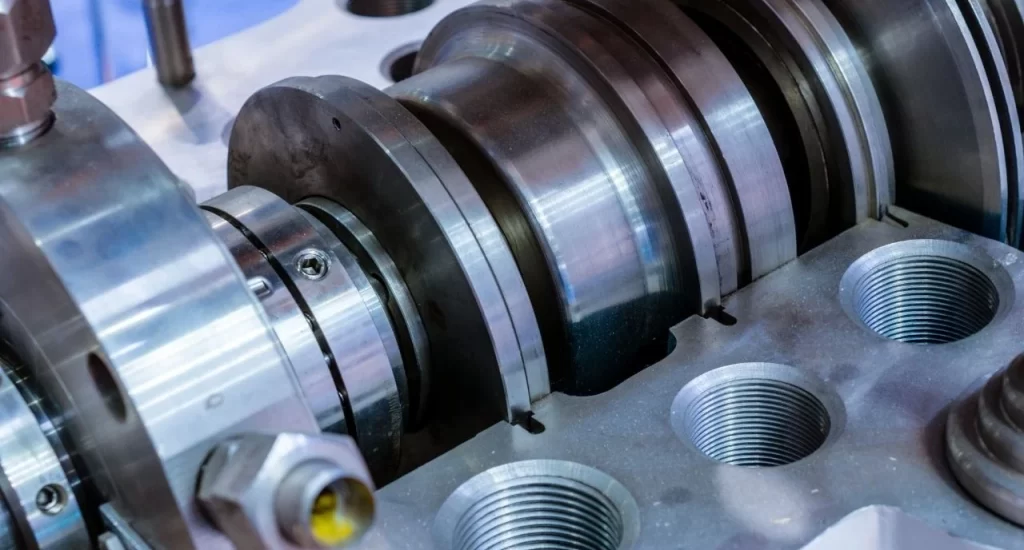

Engine

Cylinder seal: The cylinder gasket is used to seal the joint surface between the cylinder block and the cylinder head to prevent the leakage of high-temperature and high-pressure gas, and to prevent coolant and lubricating oil from entering the cylinder. It is usually composed of metal and non-metallic materials, and can withstand the high temperature, high pressure and vibration of the engine when it is working. The piston ring is installed in the ring groove of the piston, which is divided into gas ring and oil ring. The gas ring mainly prevents the gas from leaking from the piston and the cylinder wall to the crankcase to ensure the sealing of the cylinder; the oil ring scrapes off the excess lubricating oil on the cylinder wall to control the oil consumption.

Crankcase seal: The crankshaft oil seal is installed at the front and rear ends of the crankshaft to prevent the lubricating oil in the crankcase from leaking to the outside of the engine. It is generally made of materials such as rubber or fluororubber, has good oil resistance and wear resistance, and can maintain a reliable seal on the high-speed rotating crankshaft.

Hydraulic system

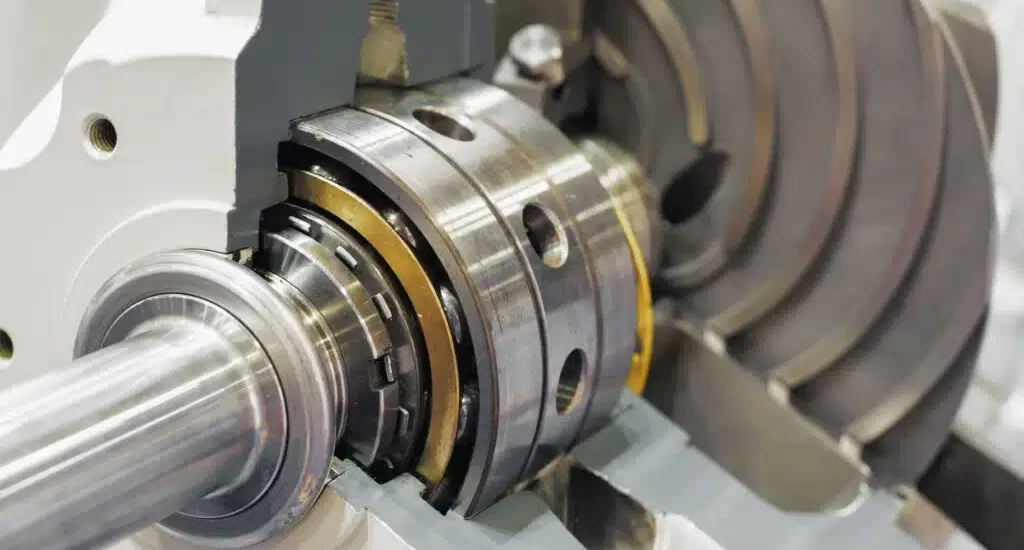

Pump and motor seals: The shaft seals of hydraulic pumps and hydraulic motors usually use mechanical seals or lip seals to prevent hydraulic oil from leaking from the gap between the shaft and the housing, ensuring the normal operation of the pump and motor. O-rings or sealing gaskets are also used at the inlet and outlet connections of the pump to ensure the seal between the pipeline and the pump body to prevent hydraulic oil leakage.

Hydraulic cylinder seals: Piston seals are used to seal the gap between the piston and the cylinder barrel in the hydraulic cylinder to prevent hydraulic oil from leaking on both sides of the piston and ensure the thrust and pull of the hydraulic cylinder. Common piston seals include O-rings, Y-rings, V-rings, etc. The piston rod seal is installed at the cylinder head of the hydraulic cylinder to seal the gap between the piston rod and the cylinder head to prevent hydraulic oil from leaking out of the cylinder and prevent impurities such as dust and moisture from entering the hydraulic cylinder.

Reducer

Input and output shaft sealing: The input and output shafts of the reducer are generally sealed with oil seals to prevent the lubricating oil from leaking from the gap between the shaft and the housing. Common oil seals include skeleton oil seals and skeletonless oil seals. Skeleton oil seals have good rigidity and sealing properties and are suitable for high-speed rotating shafts; skeletonless oil seals have good flexibility and are suitable for low-speed and light-loaded shafts.

Housing joint surface sealing: The upper and lower joint surfaces of the reducer housing are usually sealed with sealing gaskets or sealants to prevent the lubricating oil from leaking from the joint surfaces. Sealing gaskets are generally made of rubber, asbestos and other materials, and have certain elasticity and sealing properties; sealants can fill the tiny gaps of the joint surfaces to form a reliable seal.

Compressor

Reciprocating compressor: The seal between the piston and the cylinder is sealed by piston rings and stuffing box. The piston ring is similar to that in the engine, which is used to seal the gap between the piston and the cylinder wall to prevent compressed gas leakage. The stuffing box seal is installed at the part where the piston rod passes through the cylinder head. It consists of multiple sets of packing rings and can effectively seal the gap between the piston rod and the cylinder head to prevent gas leakage.

Rotary compressor: The screw compressor uses a labyrinth seal or floating seal between the male and female rotors and the casing to reduce gas leakage between the rotor and the casing and improve the efficiency of the compressor. The seal between the moving scroll and the fixed scroll of the scroll compressor uses a sealing gasket and sealant to ensure the sealing between the moving scroll and the fixed scroll to prevent compressed gas leakage.

D Eleven supply standard and customized seals for Mechanical industry. Include as below:

For more information, contact our expert technical team.

Call+8613504978509 or email info@d-eleven.cn