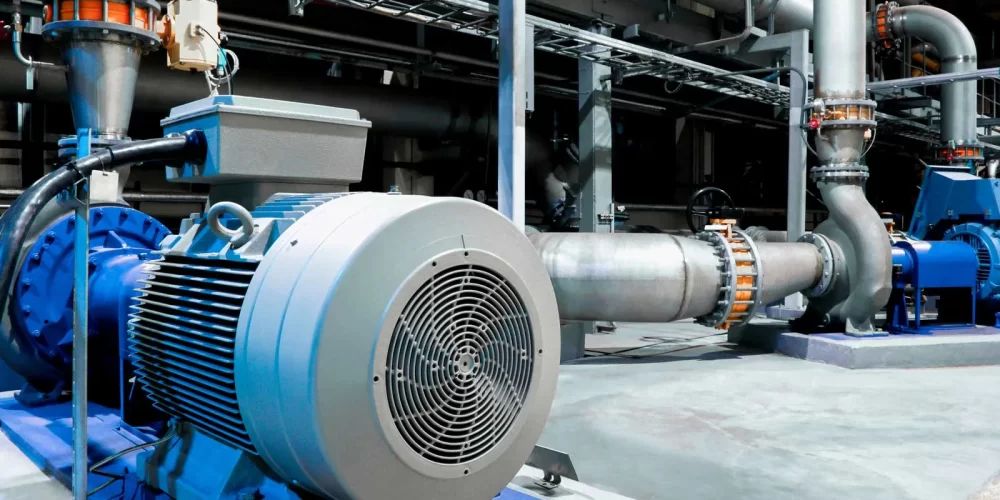

Pump And Valve

Seals are key components in pump and valve equipment to ensure normal operation and prevent medium leakage. They are widely used in the field of pumps and valves.

- Home

- Lq-project

- Pump and Valve

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

(17-1) NO23, Beisizhong Lu, Tiexi District, Shenyang, Liaoning,China.

Pump Field Centrifugal Pumps

Axial seal: Mechanical seal is usually used, which relies on the dynamic ring and the static ring to fit tightly under the action of fluid pressure and elastic elements to form a sealing surface to prevent the medium from leaking in the axial direction. It is suitable for conveying various media such as clean water and oil. Soft packing seal is also common. It is made of materials such as asbestos impregnated with lubricants and graphite. The seal is achieved by pressing the packing with a gland. It is often used in occasions where leakage requirements are not particularly strict.

Radial seal: The interstage seal of a multistage centrifugal pump often uses a labyrinth seal, which uses a series of annular sealing teeth arranged in sequence to form a tortuous channel with the shaft to increase the medium leakage resistance and reduce interstage leakage. In addition, the sealing ring between the impeller and the pump casing is also a radial seal, which can prevent the high-pressure medium at the impeller outlet from leaking to the low-pressure area at the inlet, thereby improving the efficiency of the pump.

Positive displacement pump

Reciprocating pump: The seal between the piston and the cylinder liner generally uses a piston ring, which is mostly made of wear-resistant metal or non-metallic materials. It can adapt to reciprocating motion, effectively seal the working medium and prevent leakage. For reciprocating pumps that transport high-viscosity and high-pressure media, a combined sealing structure may also be used, such as installing auxiliary seals such as O-rings on the outside of the piston ring to improve sealing reliability.

Rotor pump: Lip seals are often used between the rotor and the pump housing. The lip edge of the lip seal fits tightly with the rotor surface to prevent medium leakage. It has good sealing performance and wear resistance and is suitable for transporting media with hygienic requirements such as food and medicine.

Valve field

Gate valve: A packing seal is generally used between the valve stem and the valve cover. The gap between the valve stem and the valve cover is filled with materials such as packing, and the seal is achieved by pressing the gland to prevent the medium from leaking along the valve stem. The seal between the gate and the valve seat usually relies on the close fit between the sealing surface of the gate and the valve seat. Metal seals or non-metal seals can be used. Metal seals are suitable for harsh working conditions such as high temperature and high pressure, while non-metal seals have better sealing performance and lower friction coefficient.

Ball valve: The seal between the ball and the valve seat is the key to the ball valve. Common ones are soft seals and hard seals. Soft-sealed ball valves usually use materials such as polytetrafluoroethylene as valve seat sealing materials, which fit closely with the ball to achieve good sealing effects. They are suitable for low temperature, low pressure and corrosive media. Hard-sealed ball valves use metal materials as sealing surfaces. Through the grinding and matching of the ball and the valve seat, they have better sealing performance under high temperature, high pressure and wear conditions.

Butterfly valve: The seal between the butterfly plate and the valve seat is generally made of a sealing ring made of elastic materials such as rubber or plastic, which is installed on the valve seat. When the butterfly plate is closed, it is in close contact with the sealing ring to achieve sealing. For some special working conditions, such as high temperature, high pressure or highly corrosive media, metal sealing butterfly valves can also be used. The special sealing structure and materials ensure the sealing performance and reliability of the butterfly valve.

D Eleven supply standard and customized seals for Automation industry. Include as below:

For more information, contact our expert technical team.

Call+8613504978509 or email info@d-eleven.cn